Easy transformation of any elevator into a regenerative one

Improves your elevator energy classification

Reduce Co2 Emissions and boost your net zero

Save up to 70% of your elevator energy

Energy from breaking is saved and stored.

98% Efficiency

Recovers and Stores the energy generated by the elevator to return in the next consumption trip or to support the drive standby

No regeneration to the grid and therefore no harmonic generator problems

Suitable for new or existing traction elevators

A simple three wire connections to any drive that doesn’t interfere with existing electronics.

A typical traction elevator car is counterweighted. When the counter weight goes down the elevator car goes up and vice versa.

When load of the traction elevator car is heavier than the counter weight the car goes down due to the effect of gravity. The traction elevator motor acts as a brake generating energy.

The same occurs when the traction elevator car goes up unloaded weighing less that the counterweight. As the counter weight is now heavier and gravity moves it down the motor generates energy again in the same way a dynamo does.

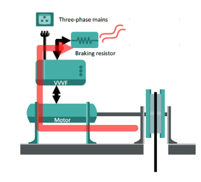

The energy is allowed to dissipate as heat within a braking resistor. These resistors are triggered by the drive mechanism, serving to shield it from internal overvoltage by wasting surplus energy from the system.

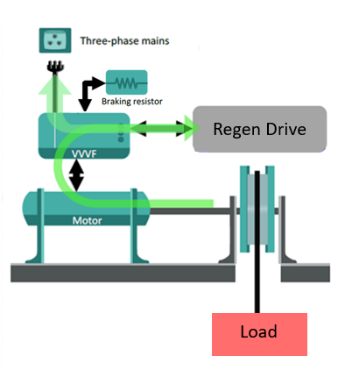

Returning the excess energy back to the grid accomplished through a regenerative drive. Instead of a conventional unidirectional drive, a bi-directional (regenerative) drive is utilized, sending surplus energy back into the AC grid. However, this energy needs to be utilized by other energy-consuming systems within the building at the time it’s generated.

With this type of drive, elevator energy consumption actually increases compared to the first option due to the higher standby consumption of regenerative drives. The advantage lies in the energy injected into the building for other systems to utilize. Nonetheless, regenerative drives necessitate special filters to ensure that the generated energy meets the required standards.

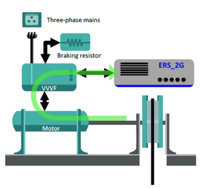

This system is capable of storing this energy, in supercapacitors, allowing it to return the same elevator and be used automatically to help power the elevator when next required. This reduces the overall consumption and the energy required from the grid.

The bi-directional energy storage process is carried out in direct current, avoiding additional filtering requirements.